OEM Manufacturer High Speed Steel For Circular Saw Dealer - HIGH SPEED STEEL – Histar

OEM Manufacturer High Speed Steel For Circular Saw Dealer - HIGH SPEED STEEL – Histar Detail:

Property:

- Very good wear resistance

- High pressure resistance

- Great toughness

Application:

HIGH SPEED steels have been named to show their ability to resist softening at elevated temperatures therefore maintaining a sharp cutting edge when cuts are heavy and speeds are high. They are the most highly alloyed of all of the tool steel types. They normally contain comparatively large amounts of tungsten or molybdenum, chromium, Cobalt and vanadium, along with carbon.

Two groups are available: Molybdenum Types and Tungsten Types

THE MOLYBDENUM high speed tool steels contain 3.50 to 9.50% molybdenum. They characteristically contain 4.00% tungsten, and 1.00 to 5.00% vanadium. Carbon is fairly high—0.80 to 1.50%. Applications cover a wide range of cutting tools. Examples include these: twist drills, reamers, milling cutters, lathe and planer tools, cutoff knives, and insert cutter blades.

THE TUNGSTEN high speed tool steels have 12.00 to 20.00% tungsten. They also have substantial amounts of chromium and vanadium, and some have considerable amounts of cobalt. Carbon is high—0.70 to 1.50%, depending on the grade. Tooling uses include bits, drills, reamers, taps, broaches, milling cutters, hobs, punches, and dies.

Mainly HIGH SPEED STEEL Grade No. We Supplied:

| HISTAR |

DIN |

ASTM |

JIS |

| HSG6 | 1.3343 | M2 | SKH51 |

| HSG6CO | M2 Mod. | ||

| HSG18 | 1.3355 | T1 | SKH2 |

| HSG35 | 1.3243 | M35 | SKH35 |

| HSG42 | 1.3247 | M42 | SKH59 |

| HSG64 | M4 | SKH54 | |

| HSG7 | 1.3348 | M7 | SKH58 |

Size:

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

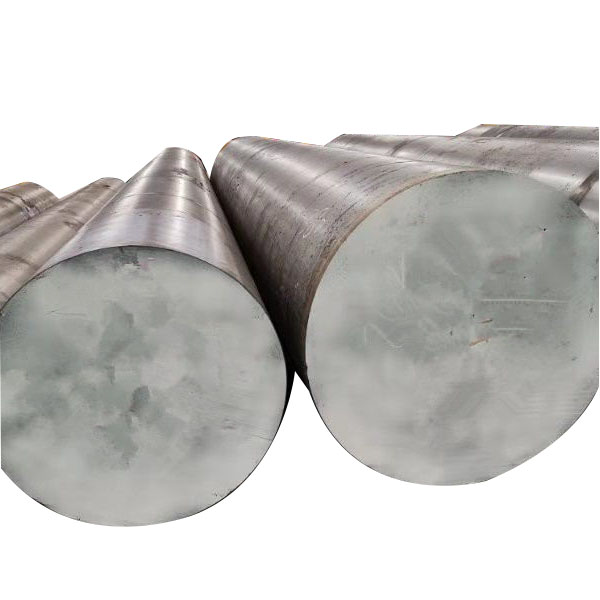

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-250 |

|

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

51X51-200X200 |

||

|

FLAT BAR |

HOT ROLLED BLACK |

FORGED BLOCK ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-200 |

50-100 X 100-200 |

||

|

STEEL SHEETS |

COLD ROLLED |

HOT ROLLED |

||

|

THICK x WIDTH xLENGTH IN MM |

1.2-3.0X600-800MM-1700-2100MM |

3.10-10.00X600-800MM-1700-2100MM |

||

|

Disc |

100-610MM DIA X1.2-10MM THICK |

|||

Chemical Composition:

|

HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

V |

W |

Co |

|||||

|

HSG6 |

1.3343 |

M2 |

0.86-0.94 |

0.20-0.45 |

0.20-0.40 |

3.75-4.50 |

4.50-5.50 |

1.70-2.10 |

5.50-6.70 |

- |

Excellent combination of wear resistance, toughness and hot hardness. Superior compressive strength for deformation resistance, reducing susceptibility to , denting and edge rollover. |

For all kind of wear resisting tools that bear vibration, Like Lathe tools, Planer tools, Drills, Taps, Reamers, Broaches, Milling cutters, Form cutters, Thread chasers, End mills, Gear cutters |

|

HSG35 |

1.3243 |

M35 |

0.87-0.95 |

0.20-0.45 |

0.20-0.45 |

3.75-4.50 |

4.50-5.50 |

1.70-2.10 |

5.50-6.70 |

4.50-5.00 |

Cobalt added M2 high speed steel in which the cobalt addition provides hot hardness, The improved hot hardness makes the steel suitable for machining high-strength and prehardened steels, high-hardness alloys |

Twist drills, taps, milling cutters, reamers, broaches, saws, knives, and hobs. |

|

HSG42 |

1.3247 |

M42 |

1.05-1.15 |

0.15-0.65 |

0.15-0.40 |

3.50-4.25 |

9.0-10.0 |

0.95-1.35 |

1.15-1.85 |

7.75-8.75 |

A premium cobalt high speed steel with very high hardness and superior hot hardness, excellent wear resistance by virtue of high heat-treated hardness, stay sharp and hard in heavy-duty and high-production cutting applications |

For complicated and accurate cutting tools for hard and high speed cutting, twist drills, taps, milling cutters, reamers, broaches, saws, knives, and thread rolling dies. |

|

HSG18 |

1.3355 |

T1 |

0.65-0.75 |

0.20-0.45 |

0.20-0.45 |

3.75-4.50 |

- |

0.90-1.30 |

17.25-18.75 |

- |

Tungsten based HSS, Good combination of toughness and red hardness. High resistance to wear and softening. Relatively easy to harden. |

Twist drills, screw cutting tools, milling cutters, file cutter’s chisels, lathe tools, planer tools, shaving tools. |

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for OEM Manufacturer High Speed Steel For Circular Saw Dealer - HIGH SPEED STEEL – Histar , The product will supply to all over the world, such as: Bangkok, Croatia, Kenya, The quality of our products is equal to OEM's quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!