Good Quality 1.2311 Milled Die Block Q+T - STAINLESS STEEL – Histar

Good Quality 1.2311 Milled Die Block Q+T - STAINLESS STEEL – Histar Detail:

Application:

The chemical composition of martensitic stainless steel is characterized by the addition of elements such as molybdenum, tungsten, vanadium, and niobium on the basis of different composition combinations of 0.1%-1.0%C and 12%-27%Cr. Because the organizational structure is a body-centered cubic structure, the strength drops sharply at high temperatures. Below 600℃, the high temperature strength is the highest among all kinds of stainless steel, and the creep strength is also the highest. 440A steel has excellent quenching and hardening performance, high hardness, and higher toughness than 440B steel and 440C steel. 440B steel is used for cutting tools, measuring tools, bearings and valves. 440B steel has higher hardness than 440A steel and higher toughness than 440C steel. 440C steel has the highest hardness among all stainless steel and heat-resistant steel, and is used for nozzles and bearings.

Mainly Stainless Steel Grade No. we supplied:

| HISTAR | DIN | ASTM | JIS |

| HSA | 1.4109 | 440A | SUS440A |

| HSB | 1.4112 | 440B | SUS440B |

| HSC | 1.4125 | 440C | SUS440C |

Size:

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

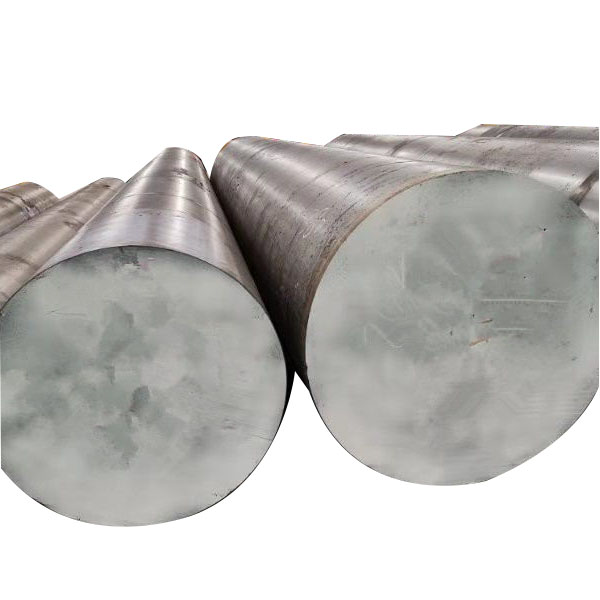

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-510 |

|

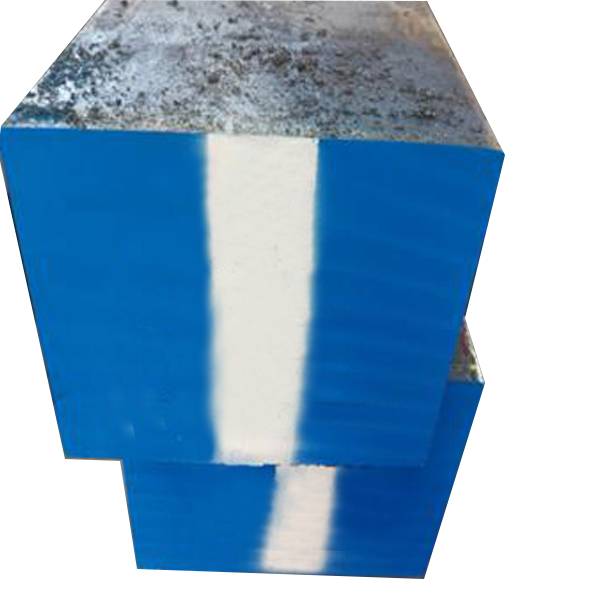

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

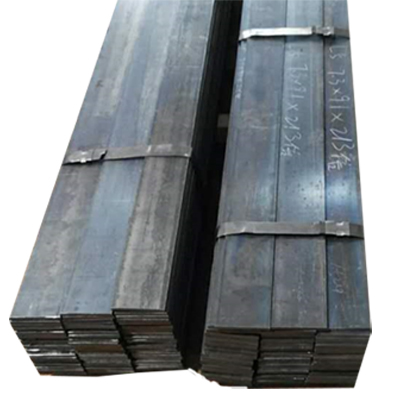

FLAT BAR |

HOT ROLLED BLACK |

FORGED BLOCK ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

STEEL SHEETS |

COLD ROLLED |

HOT ROLLED |

||

|

THICK x WIDTH xLENGTH IN MM |

1.2-3.0X600-800MM-1700-2100MM |

3.10-10.00X600-800MM-1700-2100MM |

||

|

Disc |

100-610MM DIA X1.5-10MM THICK |

|||

| HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

W |

|||||

| HSA |

1.4109 |

440A |

0.60-0.75 |

1.00 Max. |

1.00 Max. |

0.030 |

0.030 |

16.0-18.0 |

0.75 Max. |

440A steel has excellent quenching and hardening performance, high hardness, and higher toughness |

Tools, measurement, bearing with hi-resisting corrupt |

||

|

HSB |

1.4112 |

440B |

0.75-0.95 |

1.00Max |

1.00Max |

0.030 |

0.030 |

16.0-18.0 |

0.75 Max |

- |

- |

440B steel has higher hardness than 440A steel and higher toughness than 440C steel. |

cutting tools, measuring tools, bearings and valves. |

|

HSC |

1.4125 |

440C |

0.95-1.20 |

1.00Max |

1.00Max. |

0.030 |

0.030 |

16.0-18.0 |

0.75 Max |

- |

- |

440C steel has the highest hardness among all stainless steel and heat-resistant steel |

nozzles and bearings. |

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent excellent management throughout all stages of creation enables us to guarantee total buyer satisfaction for Good Quality 1.2311 Milled Die Block Q+T - STAINLESS STEEL – Histar , The product will supply to all over the world, such as: Tajikistan, Miami, Oslo, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!