Factory wholesale Forging Stainless Steel - STAINLESS STEEL – Histar

Factory wholesale Forging Stainless Steel - STAINLESS STEEL – Histar Detail:

Application:

The chemical composition of martensitic stainless steel is characterized by the addition of elements such as molybdenum, tungsten, vanadium, and niobium on the basis of different composition combinations of 0.1%-1.0%C and 12%-27%Cr. Because the organizational structure is a body-centered cubic structure, the strength drops sharply at high temperatures. Below 600℃, the high temperature strength is the highest among all kinds of stainless steel, and the creep strength is also the highest. 440A steel has excellent quenching and hardening performance, high hardness, and higher toughness than 440B steel and 440C steel. 440B steel is used for cutting tools, measuring tools, bearings and valves. 440B steel has higher hardness than 440A steel and higher toughness than 440C steel. 440C steel has the highest hardness among all stainless steel and heat-resistant steel, and is used for nozzles and bearings.

Mainly Stainless Steel Grade No. we supplied:

| HISTAR | DIN | ASTM | JIS |

| HSA | 1.4109 | 440A | SUS440A |

| HSB | 1.4112 | 440B | SUS440B |

| HSC | 1.4125 | 440C | SUS440C |

Size:

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-510 |

|

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

FLAT BAR |

HOT ROLLED BLACK |

FORGED BLOCK ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

STEEL SHEETS |

COLD ROLLED |

HOT ROLLED |

||

|

THICK x WIDTH xLENGTH IN MM |

1.2-3.0X600-800MM-1700-2100MM |

3.10-10.00X600-800MM-1700-2100MM |

||

|

Disc |

100-610MM DIA X1.5-10MM THICK |

|||

| HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

W |

|||||

| HSA |

1.4109 |

440A |

0.60-0.75 |

1.00 Max. |

1.00 Max. |

0.030 |

0.030 |

16.0-18.0 |

0.75 Max. |

440A steel has excellent quenching and hardening performance, high hardness, and higher toughness |

Tools, measurement, bearing with hi-resisting corrupt |

||

|

HSB |

1.4112 |

440B |

0.75-0.95 |

1.00Max |

1.00Max |

0.030 |

0.030 |

16.0-18.0 |

0.75 Max |

- |

- |

440B steel has higher hardness than 440A steel and higher toughness than 440C steel. |

cutting tools, measuring tools, bearings and valves. |

|

HSC |

1.4125 |

440C |

0.95-1.20 |

1.00Max |

1.00Max. |

0.030 |

0.030 |

16.0-18.0 |

0.75 Max |

- |

- |

440C steel has the highest hardness among all stainless steel and heat-resistant steel |

nozzles and bearings. |

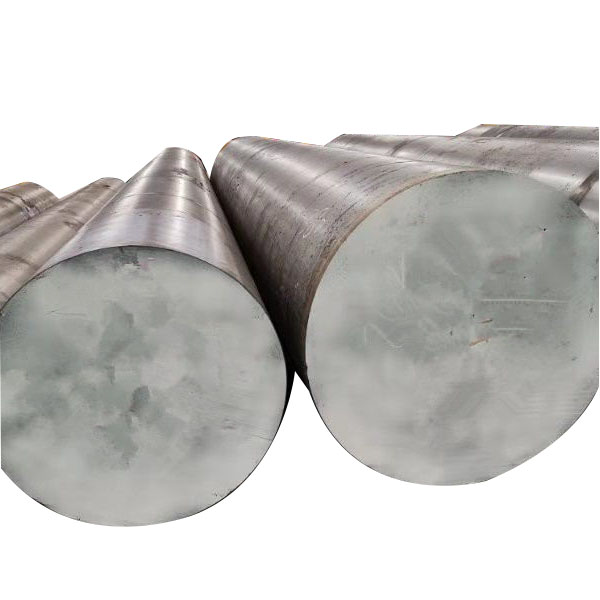

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Factory wholesale Forging Stainless Steel - STAINLESS STEEL – Histar , The product will supply to all over the world, such as: Bahrain, Rome, Swaziland, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.